There still seems to be some confusion in the marketplace surrounding specific types of tracking applications, especially when it comes to independent row, self-powered trackers (SPTs)

Fact or Fiction: 3 Biggest Myths About NEXTracker Technology

Dan Shugar | NEXTracker

I’ve worked in solar for 30 years – and for 30 years I’ve consistently underestimated the industry’s potential for growth. Build-out in the U.S. alone is now at about 1 GW a month – a figure that can largely be attributed to declining production costs as a result of various technological innovations.

I’ve worked in solar for 30 years – and for 30 years I’ve consistently underestimated the industry’s potential for growth. Build-out in the U.S. alone is now at about 1 GW a month – a figure that can largely be attributed to declining production costs as a result of various technological innovations.

Solar trackers are one of these innovations. Almost every owner, operator, and engineer I interface with in my day-to-day work recognizes the benefits provided by tracking technology. However, there still seems to be some confusion in the marketplace surrounding specific types of tracking applications, especially when it comes to independent row, self-powered trackers (SPTs). As the CEO of a company that developed the industry’s first SPT system, I find myself time and time again having to dispel myths about our products that simply are not true. Hopefully this blog will help clear up some of that confusion once and for all.

Myth #1: More motors means a higher likelihood of failure

Fact – Having individual motors control each row is not a disadvantage as it’s sometimes perceived to be. In fact, it actually increases the overall resiliency of the solar power plant by eliminating the risk of broader malfunctions that can lead to downtime. This is in contrast to mechanically linked rows, where failure of a single mechanical component can bring down a large portion of the array.

The motors used in NEXTracker systems are highly reliable — not so dissimilar to what controls a car window or refrigerator. What’s more, because the systems are mechanically balanced, the power required to move each row is very low, placing minimal stress on the internals of the motor itself.

Having independently controlled rows also provides benefits with regards to diagnostics. Each of our motors is responsible for roughly 25 kWh of panels, and by collecting data on their operation, we can see with very fine resolution how specific arrays are performing. Additionally, by monitoring motor current data in real-time, we have the capability to identify potential issues before they lead to a failure, resulting in more uptime over the life of the plant.

Myth #2: Self-powered trackers increase complexity.

Fact: Customers are often amazed when I tell them that the battery in their smartphone can actually provide enough energy to move our trackers. In fact, each motor – which produces about 0.1 horsepower, requires only 25-watts of power to orient all 80 to 90 panels on the row – a benefit made possible in large part by our tracker’s mechanically balanced design.

All NEXTracker systems are factory-equipped with a small, integrated solar generator, which eliminates the need to tie-in to an external grid or provide ground protection throughout the site. This drastically simplifies the installation process and leaves rows unimpeded for easier cleaning and maintenance. Swapping out the back-up battery pack is also a very simple process that typically can be completed in a matter of minutes.

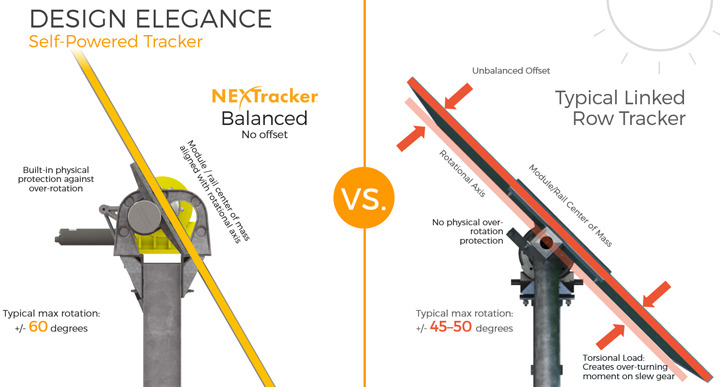

Myth #3: The only benefit of a balanced tracker design is a wider range of rotation.

Fact: Without a doubt, the two most significant advantages of our balanced tracker design are its 120 degree rotational arc and the fact that it allows owners to install rows consisting of up to 90 panels. However, it also provides a number of other benefits that sometimes get overshadowed.

For instance, our trackers feature highly durable, semi-permanent fasteners that do not loosen over time. As a result, there is no need for periodic torque checking. The fasteners were originally designed for aerospace applications and make use of an engineered slot, which provides added flexibility when it comes time to place and drive piers. This unique design mitigates geotechnical risks associated with adverse site conditions that can lead to mechanical binding of rows, such as soil settling. The end result is a more durable system that allows for accelerated construction and requires minimal maintenance.

The Road Ahead

Today, about two-thirds of all utility-scale solar systems in the U.S. are tracked. In the coming years, that figure will continue to increase as owners and operators look to unlock the full potential of their facilities. Independent row, SPT systems will represent a large part of the tracker market’s growth, serving as the foundation of newly built plants and helping drive solar as the primary source of energy worldwide.

For more information about our award-winning products, see NX Horizon and NX Fusion.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.