To convince investors of the business case, energy storage must deliver a high return on investment in terms of substantial savings and operational advantages. Equally, there can be no reduction in reliability and power quality.

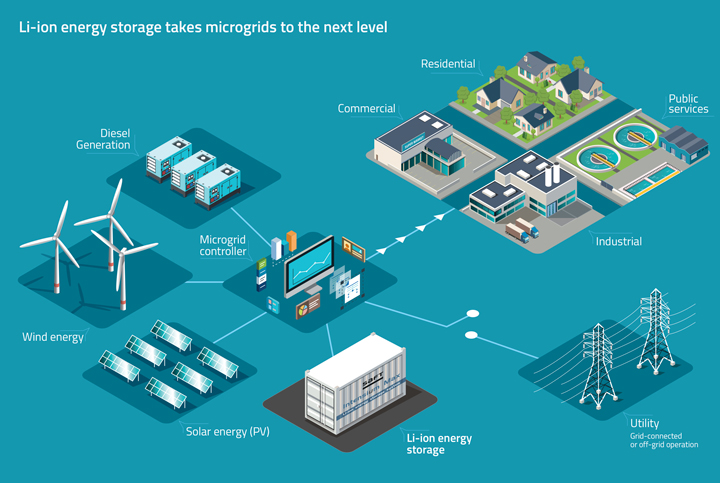

Taking Microgrids to the Next Level With Li-ion Energy Storage

Jim McDowall | Saft

There is a growing worldwide trend for microgrids due to two main drivers: the provision of power to remote communities and industrial facilities; and the need for buildings or facilities that are normally grid-connected to be able to disconnect and function independently.

Conventionally, operators have relied on diesel generators. But they are now turning to renewables and especially solar photovoltaic (PV) installations toreduce their reliance on diesel fuel.

Creating schemes in which diesel generation and PV plant complement each other can offer considerable savings in terms of the costs of fuel purchase, transport and handling as well as maintenance, since diesel gensets are required to operate for fewer hours. There are also environmental benefits from reduced greenhouse gas emissions.

Microgrids can be grid-connected or off-grid

Grid-connected microgrids can be disconnected from the grid to operate autonomously, ensuring continuity of power supply in the case of an outage. This approach is common in locations where the grid can be unreliable, such as storm-prone areas.

Off-grid microgrids typically provide power for remote villages, industrial operations and military bases. These usually have a very high cost of generation as they are totally dependent on diesel fuel and may face logistical challenges in fuel delivery.

Integrating renewable energy resources into microgrids

Adding renewables to microgrids in the form of solar and wind power is an increasingly attractive option. The cost of solar and wind per kilowatt-hour is significantly lower than diesel. But because of the intermittency of renewables, diesel gensets are still needed to ensure the stability of the grid.

Using standard power electronics, PV can contribute up to 25 percent of the power that would be generated by the diesel genset at any time. Adding dedicated software can increase the penetration of PV to around 50 percent.

When an energy storage system (ESS) is added, an operator can maximize the contribution of renewables, increasing the penetration of PV power and allowing diesel-off operation. It is possible to realize fuel savings of 50 to 75 percent. Li-ion battery systems have emerged as the technology of choice for energy storage. This is due to their high energy density that enables significant levels of storage capacity to be packed into a relatively compact footprint. Li-ion ESSs are now able to store energy at the megawatt scale, and integrated containerized systems can be connected in parallel to deliver multiple megawatt-hour storage capacity.

The three main drivers for microgrid energy storage

The first driver is that increasing the usage of PV reduces the running hours of the genset. Without energy storge, excess PV would be lost (or curtailed) but an ESS can store excess PV for use later. In addition, the power output of the PV panels is smoothed so that the genset will need to start and stop less often to compensate for the variation in PV.

Second, the diesel genset will be able to run at its point of maximum efficiency, rather than ramping up and down to meet changing demand. This reduces operational and maintenance costs as well as eliminating the need to provide spinning reserves.

Lastly, integrating energy storage enables an operator to operate their genset only when needed to support loads or to charge the battery.

How does it work in practice?

Consider an industrial microgrid with a 12 MW load. This would typically be supplied by six gensets, each rated at 2 MW. SMA has modelled the impact of adding 60 to 150 percent of PV production (between 7.5 and 18 MWp) and energy storage to fulfil the roles of power smoothing and time shifting.

Power smoothing requires a relatively small ESS that can deliver power for 20 minutes to compensate for changing weather conditions. In this case the ESS helps to ensure a smooth power output and delivers savings by avoiding the need to ramp the diesel gensets up and down. However, the gensets are still required to provide spinning reserves and recharge the battery when PV production is low.

Without an ESS, an operator can only achieve incremental savings as additional PV is incorporated. But introducing a battery helps to realize significantly more savings. In fact, for power smoothing a medium sized battery is a better option for optimizing PV penetration than adding extra panels.

In this case, a battery sized at about 40 percent of the system power (4.6 MW) and 20-minute discharge is sufficient to enable a 50 percent decrease in fuel consumption. This is estimated to save up to four million liters per year, with PV panels sized between 7.5 and 11.5 MWp. Any further increase of battery power would only allow for marginal additional fuel savings.

For timeshifting applications, a larger battery will supply two hours of energy storage so that PV energy generated during the peak hours of daylight can be used during the hours of peak demand in the morning and evening. The larger battery used in this mode enables greater levels of PV to be integrated. At up to 18 MWp of additional PV, this represents up to 150 percent of the capacity of the diesel gensets.

Running the microgrid using only PV and energy storage in this typical system, there is potential for diesel savings of almost 10 million liters per year. This does require careful system sizing and sophisticated control electronics as there is no spinning reserve immediately available. In this case the battery must be able to provide all the power if there is a sudden drop in PV production.

The rule of thumb is that, without an ESS, an operator can only achieve optimized fuel savings when PV penetration - in terms of the proportion of the load supplied by PV at any instant - is below 50 percent, with a medium-sized ESS when PV penetration is between 50 and 100 percent and with a large ESS when PV penetration rises above 100 percent.

Meeting site-specific challenges

In reality, the PV penetration and diesel savings possible at a site depend on many variables. These include:

- load profile

- PV generation profile

- environmental and economic conditions

- nature of the load

- reliability of the connection to the main grid, if one exists.

Each site is different in terms of load and PV generation profile as well as system, environmental and economic constraints.

There is no single ESS that will meet the needs of all sites. Each ESS must be considered as part of a wider system. This requires expertise to identify the optimum ESS and PV system along with well adapted controls to maximize fuel savings, integration of PV energy and minimize costs. Saft contributes to this process with high resolution Matlab based modeling of the electrical and thermal characteristics of the Li-ion battery system. This mimics exactly the real battery system behavior, and makes it possible to anticipate the evolution of battery power, state of charge and aging over time in a given application with very dynamic charge and discharge operation.

Integrating PV from the Arctic to Equator

In the extreme north, a small microgrid serves the 150-strong community of Colville Lake, located 50 miles inside the Arctic Circle in northern Canada. The 150 kW peak and 30 kW base load was met by diesel generators that had become old and unreliable. A major challenge for the community is that diesel deliveries can be made only once a year via an ice road. The distribution network operator, Northwest Territories Power Corporation (NTPC), decided to install new diesel plant and to supplement it with 50 kWp of PV.

A mathematical model of the grid determined that with an ESS, the PV can be expanded up to 140 kWp and quantified the potential fuel savings to create the business case. Saft has deployed an Intensium® Max 20M Medium Power (IM 20M) battery container with an innovative ‘Cold Temperature Package’ that provides 232 kWh of energy in combination with a 200 kW Power Conditioning System from ABB.

Also in the Arctic, Saft has delivered an Intensium® Max+ 20M containerized battery system with the same Cold Temperature Package to Kotzebue Electric Association Inc. (KEA), an electric cooperative based in Kotzebue, Alaska.

The town is not connected to the grid or to any road system and has traditionally relied on diesel generators, which have recently been augmented with a variety of wind turbines.

The 950 kWh of energy storage now allows the existing hybrid wind-diesel power system to achieve its full potential, providing cleaner, more reliable and less expensive power to the local community. The key benefits are that the KEA microgrid now has the ability to ride through fluctuations in wind output and to time-shift excess wind energy, providing significant reductions in diesel consumption.

Currently, KEA is running trials using the ESS gridforming capability, allowing diesel-off operation.

At the opposite extreme, Isotron has implemented an ESS for the world’s largest PV-diesel hybrid microgrid located in the town of Cobija, in Bolivia’s Amazon rainforest. The remote community is not grid connected and depended on 16 MW diesel generators and 5 MWp solar PV to meet its 8 MW load – a PV penetration of 62 percent.

The grid operator ENDE (Empresa Nacional de Electricidad) wanted to extend electricity coverage and reduce diesel consumption. To meet this goal, Saft has delivered an ESS capable of delivering 2.2 MW and with a capacity of 1.2 MWh.

Since it was commissioned in December 2014, the ESS has enabled the operator to switch off two gensets, saving two million liters of fuel per year.

Making the business case for energy storage

Energy storage is typically considered when operators want to reduce both their running costs and reliance on diesel power. While at the same time, the increasing cost-competitiveness of PV means that hybrid schemes are becoming more attractive. However, to convince investors of the business case, energy storage must deliver a high return on investment in terms of substantial savings and operational advantages. Equally, there can be no reduction in reliability and power quality. Stable frequency and voltage are critical in remote microgrids where communities have high dependence on a reliable power supply.

Using an ESS as part of a PV-diesel hybrid scheme requires cooperation between the developer and supplier, as well as a high level of expertise to develop the optimum layout and size of each element of the system. It is also important to understand how best to retrofit ESS and PV equipment to existing diesel plant.

Conclusion

-

The hybrid powering of remote microgrids is being driven by the increasing cost-competitiveness of renewables.

-

Storage allows the penetration of renewables to be optimized while ensuring operational excellence in terms of reliability and stability.

-

System sizing and optimization is complex and requires considerable cooperation between operator, developer and supplier.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product