Power optimizers have the advantage of finding and quantifying failures continuously during operation.

Power Optimizers Match Infrared (IR) Imaging Capabilities at Finding Module Defects

Power Optimizers Match Infrared (IR) Imaging Capabilities at Finding Module Defects

Contributed by | SolarEdge

Infrared imaging is often used for quality inspection of photovoltaic (PV) plants. This study compared both IR-inspection and module-level monitoring in terms of defective module detection and quantification of their impact on module performance.

The research tested ten rooftop PV systems installed with power optimizers connected to PV modules monitored by the SolarEdge monitoring platform. The installations consisted of roofs of differing angles and inclinations, with an average peak power of 25kWp. The installations had been in operation 1-6 years. During the study, drone-mounted IR-imaging systems measured and recorded environmental data through IR-images of the modules. The data evaluation combined the IR readings with the cumulative production data for the entire period from the SolarEdge monitoring platform, along with ambient temperature, wind speed and relative humidity from a weather data service.

Simulation and comparison of I-V and P-V curves of single modules, and strings with 20 modules, was performed to evaluate the electrical differences during module failure and variable operating conditions.

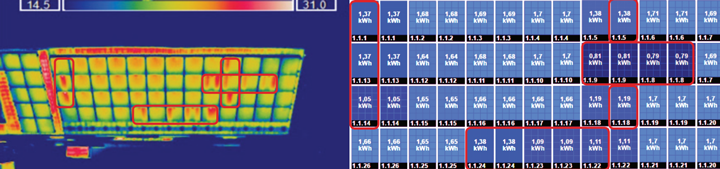

Figure 1: IR-image of a rooftop PV-plant R with several modules with one or two open-circuited substrings (OCS1 or OCS2) (left), monitoring chart showing the yield on module-level (right), E ≈ 950 W/m², Tamb ≈ 5°C.

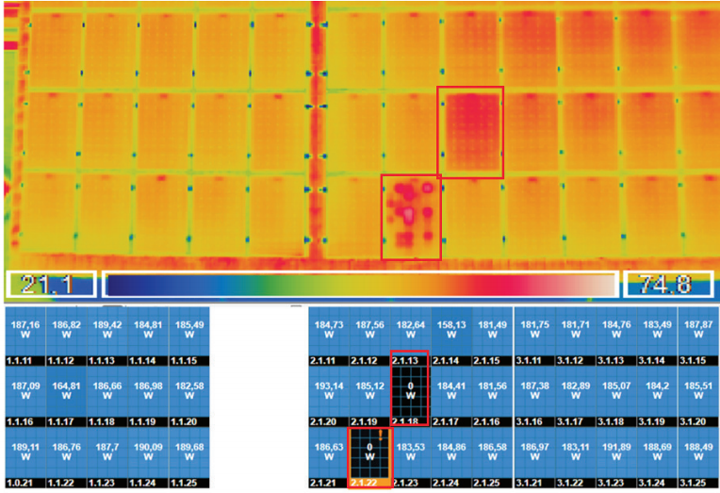

The study demonstrated significant similarities between the findings delivered by IR-imaging, and the electrical data collected from the power optimizers. IR-imaging reveals module defects such as substring failures caused by open and short circuits, bypass- diode faults, and other defects. The energy levels recorded by the power optimizers confirmed a direct correlation between these defects and module power loss and yield reduction. Both methods identified failures in the PV modules, but IR-imaging has limitations, as it does not account for variable effects, and temporal changes. IR-imaging offers information that can help identify the source of the failures and can also identify fire risks outside the modules, e.g. damage to connectors and cables. The advantage of module-level monitoring is in the provision of information that would not be detected by singular imaging measurement. Module-level monitoring detects and records failures continuously during operation, and provides contextual historical data. Furthermore, the added data regarding power and yield levels allows O&M staff to plan the most appropriate maintenance strategy to manage these defects. The study indicates that periodic IR imaging in addition to continuous monitoring via module optimizers adds value.

Conclusion and SolarEdge Solution

IR-images show a snapshot of current quality under local operating conditions, and defects can be identified and precisely located. SolarEdge power optimizers not only track and measure module performance, but also minimize mismatch-related energy losses. Furthermore, the SolarEdge monitoring platform continuously records the performance data collected from the modules and sends alerts in cases of substandard performance. Of the ten PV sites investigated, failures were detected in six of them; this reflects the importance of having a ready means to constantly monitor PV performance to locate and manage potential failures. Prompt and regular review of the data in the monitoring system enables detection of defects, optimal corrective and preventative maintenance, and ultimately contributes to improved PV performance.

Figure 2: IR-image (top) and module level monitoring (bottom) on 6.7.2017 at 12:30 h identify defective panels. Module monitoring reveals additional issues that are not clearly identified by IR-image

1 “Verifying defective PV-modules by IR-imaging and controlling with module optimizers”, by Claudia Buerhop, Frank W. Fecher, Tobias Pickel, Adrian Häring, Tim Adamski, Christian Camus, Jens Hauch and Christoph J. Brabec, representing the Bavarian Center for Applied Energy Research (ZAE Bayern) together with the Materials for Electronics and Energy Technology Institute (i-MEET) and SolarEdge Technologies GmbH. The study was presented to the 33rd European Photovoltaic Solar Energy Conference and Exhibition and was selected by the Executive Committee of the EU PVSEC 2017 for submission to “Progress in Photovoltaics”

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product