Considering A Lithium Battery For Your Electrical Back-up Station? Here's Some Facts You Need To Know

Lithium Batteries for Renewable Energy Applications

Lithium Batteries for Renewable Energy Applications

Article from | US Battery

Over the past decade, there has been a rush in the battery industry to be the first to have a deep-cycle Lithium-ion (Li) product for various applications. For those considering lithium chemistry for the benefits of maintenance-free operation and higher capacity for something like a back-up power system, it's important to know that battery manufacturers utilize a variety of cell designs and construction that can impact the quality and reliability of the battery. To make an informed decision for your particular application, it's crucial to understand the different cell types, configurations, and construction used to create them.

CYLINDRICAL VS PRISMATIC CELLS

For smaller energy storage applications, a popular option is a 12-volt G24-sized deep-cycle Li battery, and many on the market offer good amp-hour (Ah) ratings. While power and capacities may be similar, the differences are internal, with some battery manufacturers choosing to use cylindrical cells primarily due to cost and availability. A cylindrical cell is similar in size and shape to an AA battery. Creating a battery using cylindrical cells requires welding hundreds of these individual cells in series/parallel to achieve the required voltage and capacity.

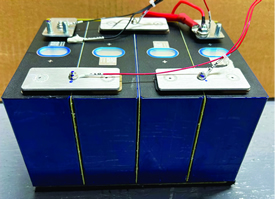

Left: US12V g24 CMYK, Right: Prismatic Li cells

Another type of Li battery cell is called a prismatic cell. These resemble a small book or stack of index cards. Some manufacturers use prismatic LFP cells because they are larger and deliver more energy per cell. Therefore, fewer prismatic cells are needed to achieve the same capacity as cylindrical cells. A 100Ah G24 group battery constructed with prismatic cells is compact and can weigh as little as 22.7 lbs. (10.3 kg). This makes them perfect for small spaces where back-up batteries are usually stored.

Another type of Li battery cell is called a prismatic cell. These resemble a small book or stack of index cards. Some manufacturers use prismatic LFP cells because they are larger and deliver more energy per cell. Therefore, fewer prismatic cells are needed to achieve the same capacity as cylindrical cells. A 100Ah G24 group battery constructed with prismatic cells is compact and can weigh as little as 22.7 lbs. (10.3 kg). This makes them perfect for small spaces where back-up batteries are usually stored.

MAKING GOOD CONNECTIONS

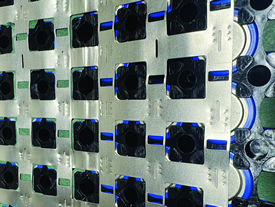

How Li battery cells are welded together also makes a difference in the battery's reliability, performance, and overall durability. Manufacturers using prismatic cells typically connect them using laser welds for precision and consistency. By comparison, lithium batteries using cylindrical cells often have small spot weld connections with limited contact area, making them susceptible to detachment from consistent vibrations.

The thickness of the material used to connect the cells also impacts the quality and performance of the batteries, with many manufacturers using thin metal sheets to connect the cylindrical cells. The thin material and small welds make them susceptible to overheating during charging and discharging, negatively affecting battery life. The thick material used to connect prismatic cells is up to 20% thicker and is engineered to handle high amp loads.

.jpg)

Left: Spot Welds, Right: Laser Welds

If your goal is safely taking advantage of lithium deep-cycle battery technology, it's important to ask your battery dealer about battery construction. If they are unfamiliar or can't get you that information, research the battery info from the manufacturer's websites. Then, ask your dealer about the differences between battery brands and look for those that provide the highest quality and reliability for your money. For more information, visit www.usbattery.com.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

US Battery

U.S. Battery Manufacturing Company

Other Articles

The Truth About Reviving Dead Batteries

Battery Recycling Can Lead to a Better Future for Energy Resources

Understanding the Chemistries of Deep-Cycle Batteries

More about US Battery

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product