A torque hinge uses friction to control the movement of a door, lid, or other type of panel. It allows the panel to be held in any position along its range of motion, without additional hardware or support.

Southco: What is a Friction/Torque Hinge?

Article from | Southco, Inc.

Why Use a Torque Hinge?

A torque hinge provides several benefits over free-swinging hinges.

Ergonomics

A torque hinge holds panels in place when users open them. This provides an easier operating experience for applications where a user’s hands may be occupied, since the hinge can hold the door for them.

Safety

If you need to prevent a panel from slamming shut, a torque hinge is an easy solution. This benefit is critical in applications where there is a risk of personal injury or equipment damage if the panel closes too quickly.

Space-saving

In small spaces, a torque hinge can eliminate the need for additional hardware or support, giving users and manufacturers more room to work with while reducing the product’s weight.

Aesthetics

A concealed torque hinge can provide a more visually appealing final product, as it can hold a panel open without visible hardware.

Durability

Where durability is important, a torque hinge can withstand repeated use and heavy loads, making it a good choice for those applications.

Overall, selecting a torque hinge can provide precise control over the movement of a panel, enhance safety, save space, improve aesthetics, and provide long-lasting performance.

Different types of Torque Hinges?

Constant Torque Hinges

Constant torque hinges provide consistent resistance throughout their entire range of motion, allowing for smooth and controlled movement. They are often used in applications where precise positioning is important, such as on medical equipment or laboratory instruments.

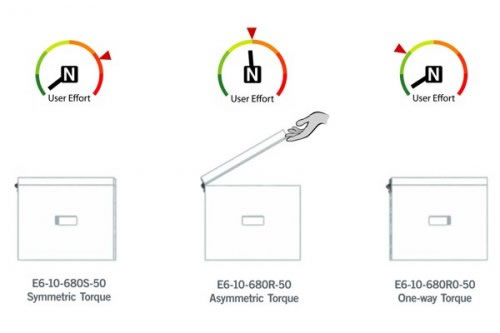

One-way Torque Hinges

One-way torque hinges provide resistance to movement in one direction only, typically allowing for free movement in the opposite direction. They are often used on lids or doors that need to be easy to open, and held open at a specific angle.

Detent Hinges

Detent hinges provide resistance to movement at specific angles, allowing the door or lid to stay open at those angles. They are often used on cabinets or other furniture where the door or lid needs to be held open while in use, and close softly when users are done.

When selecting a torque hinge, it's important to consider the specific requirements of the application and choose a hinge that provides the appropriate level of resistance and range of motion. It's also important to choose a hinge that is made from high-quality materials that can withstand the environmental conditions of the application.

Adjustable Torque Hinges

Adjustable hinges allow the user to adjust the level of resistance to movement, typically using a tool-operated adjustment mechanism. They are often used in applications where a panel’s weight may fluctuate during its lifespan, thus changing the torque requirements over time.

How to Choose the right Torque Hinge?

Panel Weight

It is important to choose a torque hinge that can support the weight of the panel it is attached to. Specifying load capacity is a key element to ensuring that the hinge has enough torque to perform effectively. Make sure to check the load capacity of the hinge and compare it to the weight of the panel.

Movement Range

Consider the range of motion needed for the panel and choose a torque hinge that can provide the necessary torque across that range. The right torque hinge should keep a panel easy to open and close while keeping it in place when users need it.

Torque Needed

Some torque hinges allow users to adjust the amount of torque they provide, which can be useful for fine-tuning position control. If users could stick something to the outside or inside of your panel, or otherwise change its weight somehow, this feature can keep the torque hinge working as intended regardless of minor weight changes.

Surrounding Environment

Where will the hinge be used? If the device will be exposed to harsh environmental factors such as extreme temperatures, moisture, or salt spray, choose a hinge that is designed to withstand those conditions. Stainless steel hinges resist corrosion, and sealed mechanisms keep the torque engine safe from threats that may come from the surrounding environment.

Mounting

Consider the mounting requirements for the hinge and ensure that it can be easily installed in your application. Whether you need a concealed, surface-mount, countersunk, or barrel-down hinge, assess the application area to find the best hinge to ensure peak performance.

Southco has a diverse range of hinge types that cover the full spectrum of torque needs. By considering these factors and carefully evaluating the requirements of your application, you can select the right torque hinge for your needs.

Application Areas for Torque Hinges

Laptop computers

Torque hinges are commonly used in laptop computers to hold the screen in place and allow for smooth and controlled movement when needed.

Medical equipment

Many types of medical equipment, such as examination tables and imaging devices, use torque hinges to allow for precise movement and positioning.

Aerospace

Torque hinges are used in aerospace applications, such as cockpit doors and cabinetry, to hold panels and doors in place during flight. Additionally, torque hinges in comfort headrests and armrests in aerospace seating allow passengers to adjust their experience for maximum comfort.

Automotive

Many types of vehicles use torque hinges in center consoles, headrests, and infotainment systems to allow for enhanced ergonomics for a premium experience.

Industrial equipment

Torque hinges are commonly used in industrial machinery and enclosures to allow easy access while controlling the movement of a panel or door to maintain a safe and secure operating environment.

Overall, torque hinges are used in a wide range of applications where controlled movement and positioning of a door or panel is required, particularly where precision, durability, and reliability are important.

How much torque is in a hinge?

Torque hinges are available in a range of torques, which are measured in newton-meters (Nm) or inch-pounds (in-lb) and refer to the amount of force required to rotate the hinge through a specific angle. The exact torque varies depending on the manufacturer and the specific model.

At Southco we offer hinges with torque from tenths of a Nm to around 20 Nm. Above that, moving the panel would be difficult or cumbersome so we offer counterbalance lift assist hinges to cover heavier applications.

The appropriate torque range for a specific application will depend on a variety of factors, including the size and weight of the door or lid, the desired opening angle, and the required level of resistance to movement.

How to calculate the right amount Torque for your Hinge?

The torque required is determined by three main factors:

- the mass (weight) of the door

- the size of the door (distance from the hinge to the centre of gravity to user applied forces)

- the desired feel and resistance to movement.

The last parameter can be subjective, so a formula to calculate the required torque (generally being force multiplied by distance) will only get you so far. Adding some level of safety factor or additional resistance to account for external forces (ex: fingers pushing on a touch screen) is recommended.

A good starting point is usually to multiply the force acting on the hinge by the distance to the hinge and adding around 30% for "feel" Please contact Southco and one of our experienced engineers will be able to support the selection of the right solution for your application.

Closing Thoughts on Torque Hinges

Torque hinges provide a smooth and consistent range of motion, and can hold the door or panel open while keeping users’ hands free. They are the ideal solution for controlling the movement and positioning of a door or panel.

Their ability to provide precise and repeatable positioning makes them suitable for use in a wide range of applications, including medical equipment, automotive, industrial machinery, and aerospace components. They are also available in a variety of sizes and materials to accommodate different door or panel sizes and weights, and to match different aesthetic requirements.

No matter what your application is, if you need to precisely control a panel’s movement and keep users’ hands free, there is a torque hinge that will work for you.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product