One solar PV innovation has largely flown under the radar: pole mounted solar electric panels. That is, mounting solar PV panels on a steel pole anchored in cement, fully capable of adjusting to daily and seasonal sun positions.

Peter Henry | Energy Concepts

Solar photovoltaic modules have been around a long time. In the late 1970s, they even made it onto the White House, where Jimmy Carter, in a fire-side chat, solemnly announced that America would never again import so much oil.

Subsequent to that, of course, Ronald Reagan trounced Mr. Carter in a watershed election and removed the panels, insisting America’s energy needs could be met through traditional sources.

How did that work out?

Last year, the United States achieved a level of foreign oil dependence that makes the 1970s seem quaint, CO 2 emissions from America’s coal plants threaten earth’s climate, and costs of fossil-fuels are set to spiral out of control risking the nation’s economy.

Not so well.

But, even though Federal priorities around renewable energy have faltered and America has fallen behind in the quest for energy independence, that does not mean nothing has changed in terms of solar PV innovations.

In fact, new policies and products abroad have flooded the industry continuously over the last decades. Countries like Germany, Spain and Japan invoked “feed-in tariffs”, paying customers as much as three times the going retail rate for excess solar generated kWhs, with the Germans PV generation surging to as much as 10% of their total national electrical production.

The result: higher efficiencies in solar panels, better quality balance-of-systems components, more effective mounting and installation protocols-- even micro-inverters that convert DC production to AC instantaneously on each individual solar panel.

Such improvements have made solar PV the single most popular renewable energy technology in the world today.

Yet interestingly, one solar PV innovation has largely flown under the radar: pole mounted solar electric panels. That is, mounting solar PV panels on a steel pole anchored in cement, fully capable of adjusting to daily and seasonal sun positions.

The advantages of “top of pole” (TOP) mounted solar arrays are substantial:

-

There is no impact to a building’s existing roof system, meaning that subsequent shingle replacement, additions or leakage can be handled without needing to deal with solar panels.

-

The architectural aesthetics of a well-conceived building are fully preserved while the energy-producing PV modules are remote and hidden from the structure.

-

Actual power production from a TOP solar array, especially one with a dual-axis tracking system, on a per-module basis, far surpass roof-mounted systems.

-

In areas where the dwelling structure is shaded, providing valuable summer cooling, the PV panels can be sited in a location that maximizes the available solar resource.

In short, TOP solar arrays are a very intelligent, efficient and sophisticated deployment of solar technology. And today’s smartest solar consumers are starting to embrace their many advantages.

According to Craig Tarr of Energy Concepts, a leading solar PV engineer in Wisconsin, TOP mounted arrays account for fully 50% of his company’s residential project installations in 2009. That’s a huge bump up from three years ago when the technology was virtually unknown in Wisconsin.

Here’s how a typical TOP mounted solar array works.

First, a site is identified that has quality access to the solar resource, i.e., the sun. That means there can be no trees, buildings or other obstacles located directly in the southern path of the proposed array.

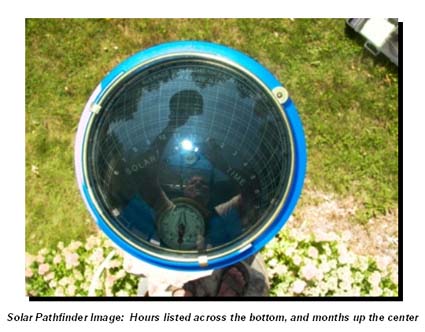

In most situations, a Solar Pathfinder is used to analyze the site and determine the exact amount of average annual hours of sunlight.

By predicting the amount of shading over the course of an entire year, and knowing the average annual sun exposure, an accurate kWh production estimate can be made. And also, very important for TOP arrays, whether or not a “dual axis tracking” mechanism is warranted.

A dual axis tracking array means that the TOP mounted system has a small motor assembly that can swing the entire panel assembly up or down and side-to-side. Over the course of a day and an entire season, the array is adjusted constantly so that it points directly at the sun, maximizing solar production.

While dual axis trackers can cost as much as 10% more to install initially--and as the only moving part in a solar array can also result in maintenance expenses (as much as 5% of total system cost in its lifetime)--they will produce as much as 20% more kWhs annually.

The key to understanding when they are warranted is to look at the east and west horizon lines: if they are largely free of trees or other obstacles, likely, the extra investment in a tracker is worthwhile. A professional solar site assessor can say for certain when and where a dual axis tracker is warranted.

In any case, tracker or not, a typical TOP system involves a fair amount of heavy equipment, some cement, a trench line back to the location of the main electric panel, and professional electrical work installing the balance-of-systems components.

It is not something a do-it-yourselfer should even think about trying, and yet, an experienced installation firm will make this job seem pretty routine.

It all starts by excavating a foundation hole to a depth of @ 9 feet for the 18’ steel pole.

The excavated foundation will require rebar caging to prevent cracking and enhance integrity. In most cases, you can save cement by using a pre-formed sonotube. Still, in all, as much as 3 yards of cement may be needed to anchor the steel pole securely in the foundation opening.

A word to the wise: make certain that your proposed project has been designed and approved by a fully licensed Professional Engineer. Anything less can lead to a malfunction or a system inefficiency which, on a large investment like this, can turn a really good idea into a disaster overnight.

Another good reason not to try this yourself: trenching the electrical run back to the service panel to a depth of 36”. Not fun without the right equipment.

Conduit is placed in the trench to house the electrical wire and protect it from a variety of potential ills: rodents, water damage, and homeowners out digging in the yard.

I did mention that the site needs to be accessible to heavy equipment, didn’t I? Because, if you can’t back a cement truck up to the “pole hole”, all bets are off in terms of installation cost.

One interesting facet of a TOP mounted solar array is that it doesn’t happen in a day, or even in a week. In fact, you may find yourself getting antsy for the job to be done and the solar panels to be producing actual electricity. The foundation has to cure for four full weeks before any panels can be mounted.

But, happily, the day does come when the panels are ready to go up on the pole. Again, this is not a do-it-yourself operation. Both of these guys are fully licensed professional electricians with years of experience in renewable energy installations.

Though the panels, in this case SunPower 230 watt modules, are usually “plug and play”, i.e. ready for easy aggregation into a single wire, they do each require grounding to the array frame. And the entire array requires grounding, both at the pole and, through a neutral wire, back to the panel.

Having an array professionally installed by a licensed electrician means that your homeowner’s insurance company has no qualms about covering the array, or paying on the policy should an act of God, like a lightning strike, ever occur. And no, a fully grounded solar array is not a more likely candidate for lightning strikes than any other structure.

Meanwhile, back at the service panel, there is a whole lot of “re-thinking” going on about how to arrange and combine your current electrical service with the new array. In many cases, that means incorporating the new DC to AC inverter equipment, which smoothes out the electric charge and produces grid-compatible power. But, in some cases, may include a whole new electric service, since NEC codes do not permit total solar production entering the panel to exceed 20% of the panel’s rated capacity. Yet another reason to have a professional electrician handle the job.

There may have been times in the past few decades when solar arrays could be put in willy-nilly by dedicated amateurs learning on the fly. Those days are gone for good. Starting in 2012 in some states, only licensed electricians will be allowed to incorporate renewable energy technologies into an electrical service panel. That may mean that certain costs go up, but so will the quality, reliability and safety of installations.

Solar modules themselves are not very heavy. The panels pictured here only weigh about 30 lbs. each. And, in truth, the weight involved in panel arrays has never been--by itself--a threat to building integrity, or a reason to not put panels on a roof.

The real danger with solar panels, and this is true of TOP mounts as well, is wind loading. Engineers must consider arrays experiencing wind speeds of up to 100 mph and how those forces will be successfully resisted. On a roof-mounted system, this can mean beefing up the truss structure of a building. With TOP mounts however, the engineering happens in the cement foundation and the size of the steel pole, in this case, an 8” x 8” x 18’ 1/4 “ steel beam capable of withstanding hurricane force winds. With TOP mounts the engineering is the design.

And along with the quality design in a TOP mounted solar array, a homeowner needs to ensure that the panel mounting, harness components and wiring are well thought through and professionally executed. That means hiring an installer with experience, integrity and an excellent over-all understanding of system design and components.

At the end of the day, a TOP mount system will cost in the range of $45,000 before state, federal and utility incentives, which can trim that by 50%, or more if the array is hooked to a business meter. The last thing you want with that level of investment is to have loose wires or shoddy workmanship.

The array featured in this article will produce in the range of 6,000 kWhs annually--about twice as much power as consumed at this site-- with an estimated payback (assuming 7% electricity inflation and 50% cost incentives) of around 18 years. If electric costs explode, that payback period will go down considerably.

Like 95% of all solar systems installed today, the one featured here is a “grid-tied” system, meaning that excess electricity is fed back through the service panel and onto the grid. A bi-directional meter is installed which keeps track of the “net” flow of electrons into and out of the building. During the day the meter will likely be spinning backward, and at night, more power will be consumed than produced.

This concept, “net metering” is part of a Federal policy that requires States to establish clear rules and guidelines for how public utilities will compensate excess power production at distributed sites. In many states, homeowners who over-produce their consumption are repaid at the full retail rate of electricity. While this may sound fair, it pales in comparison to Germany, Spain and Japan, where “feedback tariffs” -- paying as much as three times the retail rate for excess production -- have resulted in homeowners comparing investments in solar energy against standard financial instruments like stocks and bonds.

Most Americans tend to think of solar PV in a fairly monotonous and even monochrome manner: put some generic and fairly unsightly PV panels up on the roof and maybe the system will do enough to keep the lights running. But, while we have been busy investing in highways and coal plants, solar PV has advanced way beyond that. With thin film applications, building integrated solar and remote TOP mount systems, there are myriad options that maintain building aesthetics while producing substantial amounts of power.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product