This article reviews the recent history of PV monitoring; the shift from single-meter systems to module-level control using highly reliable electronics, and future direction of the industry towards active system management from utility-scale solar farms down to the residential PV system.

Sjuli Beekhuis | Tigo Energy Inc.

Introduction:

As the PV industry matures, there is an increasing appetite for PV system monitoring, visibility and data granularity, as the value of the kWh produced is increased due to feed-in-tariffs and the trading of Solar Renewable Energy Credits (SREC’s). Although current monitoring systems are not as sophisticated as monitoring systems in other industries such as natural gas power plants and computer networks, there are new innovations in system-aided management of modules and the array, performance modeling, safety and intelligent maintenance scheduling. This article reviews the recent history of PV monitoring; the shift from single-meter systems to module-level control using highly reliable electronics, and future direction of the industry towards active system management from utility-scale solar farms down to the residential PV system.

Solar Monitoring:

Before 2005, a PV system owner or operator had to go onsite and look at a meter connected to the AC output of the inverter to determine if the system was feeding energy to the grid. Some inverters had a one-line LCD display that showed voltage and instantaneous AC output; toggling through the display would give some data on total power produced for the day and lifetime of the system. Remote monitoring capabilities were often custom hardware and software packages that would read data at intervals and transmit it to a server in daily uploads. This was a common practice for larger commercial and utility-scale systems that could absorb the costs of additional equipment into the system – the payback was increased uptime and the ability to remotely determine if a system was up and running within 15 to 20% of expected system output. An onsite pyranometer, (which measures the amount of light available in W/m2 ) ambient temperature sensors and anemometer (which measures the wind speed and direction) determined onsite environmental conditions and increased the accuracy of the predicted output. These systems were too costly for the average residential PV system, and metering and monitoring packages too complicated for the average homeowner to easily get value from them.

With the spread of the Internet and the availability of computers in the home, companies like Fat Spaniel Technologies and Draker Laboratories developed web-based tools for connecting to inverter output, giving PV system owners and installers access to the current and historical data of their systems, in easy to navigate views. This gave a higher level of visibility into system performance, and some systems could send automated alerts if the inverter or system went down. Now most inverter companies offer some type of near-real time web-based monitoring for their systems, and some installers offer a monitoring and performance package that allows a residential or commercial system owner the ability to log into a website and check on the status of their system. Many include applications for iPhones and other smart phones so that installers and system owners can access their data on the go.

In other industries, there are significantly more sensors and data about the system than what a typical PV system provides. A natural gas power plant has thousands of sensors and data points being provided on a second-by-second basis to the plant operators and grid controllers. With this granularity of data, it is easy to predict performance and when optimal maintenance should be performed. It costs thousands to shut a natural gas plant down for maintenance and bring it back up again so the cost of the monitoring has a benefit over the life of the plant. A computer network has a significant amount of information about the data flow, availability of bandwidth, number of processes running on each computer and printer, whether the printer has enough ink, if there are viruses in the system, and who is looking at which sites on the Internet…and the system can send appropriate alerts if performance drops below a certain level. Businesses rely on computer networks to run efficiently so tools were developed to allow the systems administrators to run a LAN/WAN (Local/Wide Area Network) from any of the nodes and quickly find, isolate and resolve system issues remotely. The ability to monitor and control systems is available through current technologies – it has simply not been applied to PV systems because of the small number of PV systems installed compared to other types of power plants and lack of standards that would apply to all sized of systems. The US Department of Energy (DOE) states the following in their vision statement about the future of PV power plants in the US: (1)

Solar Energy Grid Integration Systems (SEGIS) concept will be key to achieving high penetration of photovoltaic (PV) systems into the utility grid. Advanced, integrated inverter/controllers will be the enabling technology to maximize the benefits of residential and commercial solar energy systems, both to the systems owners and to the utility distribution network as a whole. The value of the energy provided by these solar systems will increase through advanced communication interfaces and controls while the reliability of electrical service, both for solar and non-solar customers, will also increase.

The US Department of Energy (DOE) is spending millions on grants to achieve this vision and new technologies for advanced communications and controls are being developed and brought to market through their support.

New Trends: Advances in Automated Management (System Controlled)

There are ever more sophisticated and granular methods of extracting data from a PV system and new software to predict potential output or issues with the system. One of the most exciting developments in hardware technology is the notion of the “Smart” PV module – electronics on the PV panel or in the Junction-Box that sense the voltage, current and temperature of each module and send that data to a central processor. Advanced intelligence within the array and 2-way communication between the module and the central controller, unlocks the ability for control systems to automate performance tuning with additional safeguards. Examples of new capabilities include dynamic power point tracking at the module level, automatic safety detection (such as arc fault prevention), nighttime theft monitoring, and real-time grid response.

It is possible to influence the MPP (maximum power point) of each PV module and create more power output from each module in the string. An increase in the kWh output of the array means a faster payback from the system as a whole, as well as allowing the inverter and modules to operate more efficiently, and extending their operating life. Data from existing systems show that even well-matched strings of modules can have voltage output differences due to panel aging, differences in temperature, soiling or wiring issues can create up to 15% differences in voltage output of a string.(2) The modules performing sub-optimally drag down the rest of the string and cause power losses in even the better performing modules.

Differences in voltage between modules in an unshaded string.

The opportunity to correct differences between module voltage outputs within the string is greater than the typical mismatch of string to string currents (as they are in parallel while the modules are in series) see string current data from the same system, below.

There is an opportunity to gain as much as half of the energy back by correcting the mismatch at the module level – in the case above where there is a difference of 15% between the best and worst performing modules, 7% of that energy can be regained through module-level MPP.

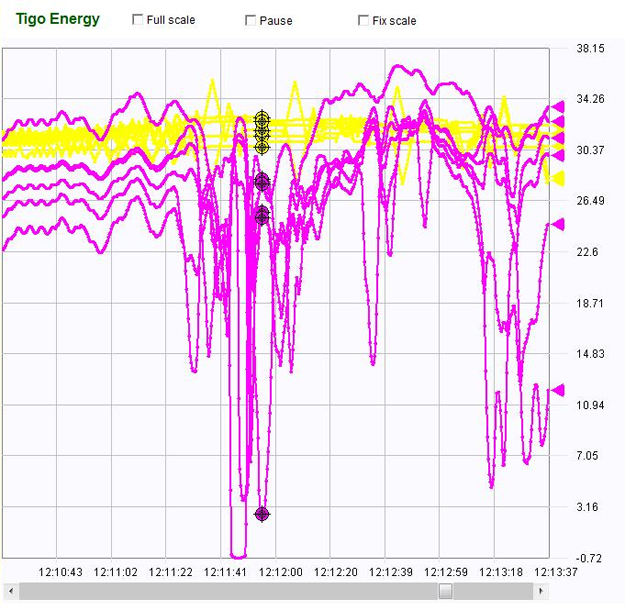

Increase in voltage stability using module MPP – yellow is module MPP and pink is standard string MPP

In this graph the output of module-level MPP is compared to standard string-level MPP and it is easy to visualize that the modules in yellow that are tracking and adjusting MPP at the module level are creating a significantly higher kWh output than the modules in pink that are being controlled by the string inverter MPP.

Safety and Theft Prevention – Electronics on the module can detect problems before they cause a catastrophic event – if there is an arc fault on a module the system can detect it and shut down the module automatically and alert the system operator to the problem and pinpoint the specific module having the issue. This can also be applied to thermal over-stress from hot-spots as well as show a bypass diode malfunctioning. If the string is temporarily producing more voltage than the inverter can efficiently handle, (due to cold, clear conditions that are outside the normal operating range) the system can “clip” the input voltage to prevent inverter shutdown and keep the system running as efficiently as possible.

An additional use for the 2-way communication technology is to monitor the connections of the modules in the PV array for theft protection. In this scheme, the central controller sends a periodic signal to each module and receives an acknowledgement – if more than 2 modules in the string do not acknowledge the controller, then an alarm signal is sent to a local operator to determine if the modules have been permanently removed. For remote sites, this can be a significant savings in security and insurance costs.

Advanced Performance Modeling – With the system reporting data at one-second intervals from each PV module, as well as reporting irradiance and temperature at the same time, it simplifies the ability to model performance predictions based on specific weather conditions, module and inverter type, and geographic location. This allows for the system to develop heuristics to provide alerts if the system is not performing as expected, and allows for the use of best practices in design of future systems under similar conditions. Predicting PV performance can also allow utilities to take a more active role in the routing of energy through the transmission system so that the contribution of the PV array to the grid as a whole is utilized more efficiently.

Control of Energy Flows: Grid Response – The use of real-time system analytics along with control of PV arrays can minimize impacts to grid power disruptions by re-routing power through backup energy sources. If the grid goes down and a control system is in place, there is the opportunity to re-route the power produced to a battery storage bank or to an isolated sub-panel for emergency operations while the grid is down, making best use of the energy produced by the PV array. Control of distributed resources also allows for peak load shifting and shaving when the solar resource (and demand) is at its highest. This can result in increased peak load offset and additional savings on energy bills.

New Trends: Intelligent Operation (System-Aided Control)

As the long term performance of a solar project is analyzed, proper operation and maintenance (O&M) of the system can be as important as the original component selection and design. Often times this can also represent one of the largest percentage of the system cost. While advances in distributed intelligence enables the PV project to automatically improve performance, additional control systems and analytics can guide system owners to maximize their O&M activities. By approaching long-term system maintenance with more insight and analysis, operators can lower the costs and time spent while increasing the effectiveness and timeliness of their actions.

At commissioning, module-level debug data can be a valuable tool to check that the entire system is operating as expected. If a PV module is not operating within spec, the problem can be spotted through the software and there is no detective work needed – a look at a management console can pinpoint the underperforming module. Action can be taken to repair or replace the module when convenient, as it will not affect the other modules in the string when the system is setting MPP for each module. An advanced management system can also show which modules might benefit from cleaning, and send a report stating when the optimal time for maintenance should be scheduled.

An example of a Utility-Scale Array view – pinpointing module issues is simplified

By enabling on-site or remote system control further tools are available to assist the operator in management of PV arrays. Safety is one key area which is enhanced by the new intelligent systems. In a traditional PV array, when the sun is shining, the DC voltage of a string can run from 375V to 600V in the US, and up to 1000V in Utility-scale and European applications. Disconnecting the DC at the inverter does not stop the flow of electrons – the modules have to be physically shaded from the sun or disconnected from each other to reduce the string voltage. This can be dangerous for professionals maintaining the system, or firefighters on the roof in a fire emergency. With the ability to control each module, an operator can disconnect the string of modules or the entire array onsite or through software to increase safety at the PV array.

Predictability – For the commercial and utility-scale system operator, predictability of system output is a key to profitability. The Power Purchase Agreement (PPA) is dependent on the optimal production of the system for a positive-cash flow – any increase in uptime or kWh produced can turn a marginal system into a successful project. The ability to identify trends at the module level can allow a system operator to pinpoint exactly the areas of concern and send the right tools at the right time, saving multiple “truck rolls” and increasing the uptime of the system. If a specific module or string is having issues, the entire array does not have to be deactivated – with the control mechanism just the one string can be deactivated and the rest of the array can operate normally. The system can send an alert when the system is not performing normally – unusual events like dust, debris or bird droppings reducing the array efficiency can affect output and trigger an alarm, as well as a broken module or a component failure.

Conclusion:

With the support of the US DOE, system operators, integrators, and Power Purchase Agreement financiers, bids on new PV installations will require active management to maximize kWh output and system safety. As electronics on the module become available as a standard feature, systems from residential through utility scale will have the advanced management and control commonly found in other advanced systems such as computer networks and other energy systems.

The Tigo EnergyTM Maximizer Solution includes the features of the next generation active management systems and will lead the advances to today’s passive systems. To learn more about these products, please visit www.tigoenergy.com or (in the US) contact leading solar distributors for pricing and further information:

AEE Solar www.aeesolar.com (800) 777-6609

DC Power Systems www.dcpower-systems.com (800) 967-6917

Footnotes:

- “Solar Energy Grid integration Systems ‘Segis’ ” Program Concept Paper, Sandia National Labs and US Department of Energy, Energy Efficiency and Renewable Energy, October 2007

- “Maximizing PV solar project production over system lifetime”, by Sam Arditi and Jeffrey Krisa, Photovoltaics International second Edition, November 2008.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product