What can you do as an investor to protect your wind farm investment? What can you do as a wind farm owner to secure your wind power production? How can the trust of insurance companies for wind farm projects be improved? The solution is to find an independent inspection, testing and verification company that combines technical consultancy with project certification.

Wind energy: Why is project certification so important?

Jessica Krause | SGS Group Management Ltd

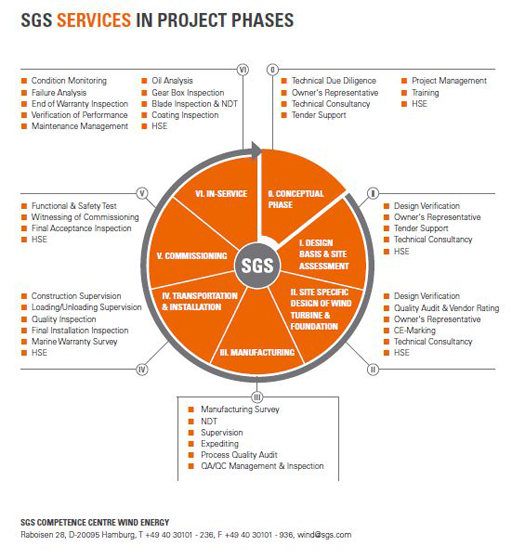

The purpose of project certification is to verify that the wind turbine and its support structures meet the site-specific conditions. The fact that a site has potentially attractive wind conditions does not mean it is suitable for wind power development. Each wind turbine model has different characteristics despite seemingly similar power ratings. These are just two of the many aspects that are taken into consideration when initiating a successful project. Project certification reduces the risk profile of a project more effectively when started earlier in the project development cycle.

The extent of project certification is optional. The project as a whole can be certified or each of the phases listed below can be independently undertaken.

-

Conceptual Phase: Third-party risk management advisory services and support is most beneficial, ensuring the decision to go ahead with a project is made with all the facts and from an informed stand point.

-

Design Basis & Site Assessment Phase: When assessing the wind farm’s location, the local environmental conditions must be evaluated. This ensures all site-specific requirements are taken into consideration during the design phase. It is important to make sure that the wind turbines and their support structures are designed to perform well at the specific site. This process also incorporates the legal mapping, which identifies the mandatory requirements and regulations the client must comply with for the specific site.

-

Site Specific Design of Wind Turbine & Foundations Phase: The verification of the detailed design includes assessment of the combined load cases for the complete wind turbine, its support structure and electrical components as well as for the transformer platform, the cables and the J-tubes.

-

Manufacturing Phase: Once the manufacturing phase commences, the effectiveness of project certification becomes more tangible. In this project phase the manufacturers are visited and inspected, the production of components is supervised and examined as well as assembly checks undertaken. The overall aim is to ensure consistently high quality during manufacture, in order to reduce potential costs from being incurred later in the project, for example a reduction in down times due to the necessity of repairs.

-

Transportation and Installation Phase: Construction, loading and unloading supervision and the final installation inspections are the penultimate stages of a wind farms development. The specific scope for this phase will depend on specific requirements related to the insurance, transportation and installation. The objective of this phase is to ensure that quality and safety of the project is maintained, from components leaving their manufacturing facilities through to their correct installation on site.

-

Commissioning Phase: The final commissioning phase covers all of the installed components of the wind turbine. It generally involves standard and functional tests for the electrical infrastructure and the turbine; it confirms a successful completion of the wind farm project and a safe start-up.

-

In-Service Phase: Professional operation and maintenance management not only assures the reliability of a wind turbine, but can also convince turbine manufacturers to offer favorable product guarantees. Knowing that qualified project operators will be on site to maintain the equipment, in addition to periodic in-service inspections, such as condition monitoring, oil analysis, and a variety of technical inspections will ensure that the condition of the wind farm is maintained over time and that the project certificate remains vaild.

The rapid growth of the wind energy sector and an increasing in the size of wind turbines provides new risks and challenges. Financial Institutions, banks, insurance companies, owners, operators and the authorities require reliability and safety assessments of wind farm projects to accurately define the technical risk involved in the development. The assessments are tailored to suit the specific verification requirements of the project.

About SGS

The SGS Group is an international inspection, verification, testing and certification company that has committed itself to providing a comprehensive range of services for the wind energy sector. These services are designed to meet the specific requirements of our clients. They cover a variety of competencies, such as project installation management, technical due diligence, inspection and certification for wind projects. To read more about SGS Wind Energy Services please visit: www.sgs.com/wind

The SGS Group is an international inspection, verification, testing and certification company that has committed itself to providing a comprehensive range of services for the wind energy sector. These services are designed to meet the specific requirements of our clients. They cover a variety of competencies, such as project installation management, technical due diligence, inspection and certification for wind projects. To read more about SGS Wind Energy Services please visit: www.sgs.com/wind

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product

U.S. BATTERY RENEWABLE ENERGY SERIES DEEP CYCLE BATTERIES

Our RE Series batteries are designed to provide the highest peak capacity, longest cycle life, and greatest reliability for use in industrial or residential renewable energy applications. Renewable Energy Series batteries utilize the company's exclusive XC2™ formulation and Diamond Plate Technology® to create the industry's most efficient battery plates, delivering greater watt-hours per liter and watt-hours per kilogram than any other flooded lead-acid battery in the market. Our Deep Cycle batteries are engineered to work with solar panels as well as other renewable energy applications.