Images of the 3 bladed wind engines are now seen everywhere and they have come to symbolize intelligent energy creation for virtually everyone but are these designs actually the most efficient ones possible? No one seems to know their efficiency so that vital issue is completely overlooked and rarely discussed. Efficiency is important to all.

Lewis M. Dickens III (Bill)

The continuum of wind powered machines has a very long history unlike that of solar powered membranes. One immediately thinks of the Greek island of Mykonos, and the Dutch windmills which have served for centuries close to a millennia and actually they were also found in Spain, England, Germany and elsewhere in Europe.

Sailing cultures understood the power of the wind so it is no wonder that windmills, actually wind engines, were first created in areas that depended upon sailing vessels for commerce. And it is quite logical that canvas was used as the resistive element that captured the wind power since sails on boats had a similar function but for an entirely different end.

Wikipedia has a good explanation of the history of such wind engines. They were called windmills, since for the most part, the practical use was for the milling or grinding of grain for the purpose of baking bread which was a staple throughout Europe. One immediately conjures up images of the Dutch and their dykes and farming developments and of Don Quixote upon the mention of the word.

As the US evolved with the expansion westward and the establishment of farms throughout the Midwest and Western States after the Civil War, farming created the necessity of having pumps to pull water up from the ground and so Aermotor in Chicago and other similar companies producing competitive products became ubiquitous and Iconic in farming country. You can still see these machines in various conditions if you drive off from the Expressways. They worked and they worked well for many years. And some of the companies still exist, producing the same product for over 130 years. And there are museums and special interest groups concerned with wind engines. In Michigan, the Amish in Centerville are known for keeping them running.

The oil crises of the 1970’s and afterward awakened the need for being careful in the use of energy, and the more recent social movements founded by Professors and college students and an increasingly more technologically developed and intelligent society have expanded interest and demand rapidly in the last 10 or so years.

Green is the new mantra and all sorts of solutions to our energy needs are being developed. It is evident that the efficiencies of solar powered solutions are always established for comparison. Why not for the wind engines?

Now after WWII NASA set about to develop some wind engines to generate electricity and the 3 bladed NASA fan has become de rigueur. Images of the 3 bladed wind engines are now seen everywhere and they have come to symbolize intelligent energy creation to virtually everyone.

But are these designs actually the most efficient ones possible? No one seems to know their efficiency so that vital issue is completely overlooked and virtually never discussed. But that is the central and most important question of all. It has been calculated that the maximum possible efficiency for a wind engine is 59%. The NASA fans are reputed to have efficiencies in the high 20% to low 30% range. What is their actual efficiency, and can it be improved upon?

An Engineer educated at the U of M “Engine” school at approximately the same time as Kelley Johnson, the father of the “Skunk Works”, entered the picture in his retirement from Ford Motor Company. His name is Bill Allison and he spent a lifetime in automotive suspension development and held many patents. One of his most interesting creations was the development of the Packard Torsion Ride Suspension. Jay Leno in his website gives a very detailed description of Bill’s work and it is very informative and delightful. http://www.jaylenosgarage.com/at-the-garage/classics/1955-packard-caribbean/

Bill was a very real mechanic, blacksmith, and artist craftsman as well as a highly refined engineer steeped in academia. I once talked with a Ford Design engineer and he mentioned being a new hire and watching Bill artfully swage a heavy rod by hand for some project that he was working on.

So in his retirement in the late 70’s Bill decided to try developing a wind engine. His first effort was to build something that looked like a combine with blades that traveled up an inclined plane and rotated over and back on down in a belt fashion over two pulleys. A subsequent ice storm taught him the importance of simplicity when the contraption disintegrated and he caught that event on camera. It was funny but painful to watch because so much effort had gone into it. But Bill laughed too and he continued.

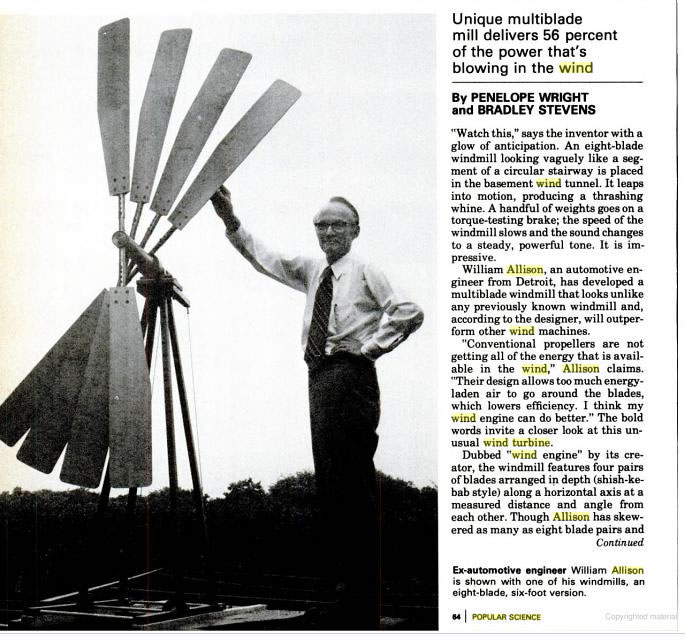

His next effort was to approach the wind engine in the traditional fashion with a series of blades on a horizontal axis mounted atop a vertical axis so that the engine could point to the wind. You can see one of his early configurations with 4 blades in a first Popular Science article. Notice the efficiency that he is announcing… some 40% and he is very proud of that. Below you see a subsequent design, one of his 8 bladed configurations.

Following simple logic he added blades and perfected them and in a later Popular Science article you can see him displaying a compound fan design. That appeared on the front cover of Popular Science in the early 80’s

Bill rationalized that complex design by saying that the different blade groups were for different wind conditions. But ultimately he simplified the design and with his meticulous engineering data acquisition using a dynamometer that he constructed. He finished the explorations with a 10 blade fan in a 12 segment configuration. He discovered that his fans were developing cones of pressure resistance like nacelles that would cause the wind to circumvent the fan. By pulling two of the blades the cone would instantly disappear and he would pull more power.

Ultimately Bill hit the theoretical maximum 59 to 60% efficiency in a test with his final design before he delved into configurations for wind engine sets in the environment.

Bill patented several fans and his final design was the simple 10 blade fan unpatented.

Here is his last patent before he quit developing fans and while it represents a very similar design its complexity was done away with in his “final” 10 blade solution.

http://www.freepatentsonline.com/4171929.pdf

Bill carefully studied each aspect of each element of the design.

Here we see his conclusion on the blades… they are stainless steel because they have to take the abuse of the weather. And Bill found that they had to be highly polished and dead flat to “pull the most power” as he would say it. He would reflect that when you are trying to extract energy from the wind you needed resistors rather than propellers. He eschewed the NASA designs as having propellers but actually they are more like sails or wings. He built many differing designs including the propeller types initially and he concluded that current theories were entirely wrong. Dead Flat and out far enough on stems to capture the wind energy without inducing any drag which would occur on the inner 1/3 of the fan disc. The designs are clever and being from Detroit, he of course, thought to use a fine engineering material for safety and longevity.

After solving the issue of the blade design he began working on configurations. You can see that he has done many but ultimately he discovered that more blades pull more power but there is a limit. When he built a 12 bladed design he found that it pulled less power than the 10 bladed designs and he set out to find out why. Bill had built a twin balance dynamometer in his basement and became convinced that most people were testing their fans in ducted wind tunnels. He concluded that the data was imperfect in the ducted designs because the confinement caused a supercharged effect that you could never achieve in the real world.

The oncoming wind actually has a choice as to where to flow and it can and it does avoid obstructions. Using dry ice and water in front of a 3’dia floor fan he noticed that a pressurized nacelle would build up in front of the fan disc and that the wind would circumvent the fan once it was established and the amount of power that could be pulled would quickly drop. And so he found that by pulling two blades opposite each other the nacelle would disappear and he could maximize the efficiency of the fans.

Seeing his dynamometer and free flow wind tunnel was a lot like looking at the Wright Brother’s models and experiments at Kitty Hawk. While the rig looked almost flimsy you could tell that he knew exactly what he was doing and he kept meticulous engineering data on all of his experiments. He dated the data and noted the temperature, barometric pressure and relative humidity as he ran each test.

And so it was that he was able to calculate the % efficiencies with his HP Calculator for each test and with the 10 bladed fans, absent 2 in a 12 blade configuration, and one day he actually pulled the 59% efficiency. Ultimately he calculated and concluded that a 16ft dia. fan could provide all the power that would be needed for the common house.

So that brings to mind that if he could achieve such efficiencies then why are we putting up fans all over the country of low efficiency designs? That simply doesn’t make sense.

Was his work correct? While I believe that it is, why isn’t there an international contest amongst both manufacturers and student engineers from engineering schools around the world, to contribute to the development of wind engine technology? Too many have prematurely concluded that the answer has been found. It hasn’t.

Certainly if we can enjoy the sight of the solar car competitions, why can’t we enjoy something similar for wind engines? Not only would there be great excitement, there could be prizes and the world would all be the better off because of it. And the winning schools would benefit too. Perhaps there could be an X Prize for wind engine development.

So I would propose such a competition and perhaps it could be called the Allison Prize in honor of a great engineer who knew exactly what he was doing. Who could put such a competition on and pull it off for the betterment of humanity?

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product

MORNINGSTAR - GenStar MPPT

GenStar MPPT is the industry's first fully integrated solar DC charging system, an all-new design with "lithium DNA" from the leader in charge controllers. Out of the box, GenStar is an overachiever-delivering legendary Morningstar quality, efficiency, power and reliability along with the latest in advanced communications and control technologies. All the most installer-requested features are on-board; additional features can be easily added via Morningstar's ReadyBlock expansion technology, with snap-in blocks that provide battery metering and monitoring, signaling and load control, and lithium battery communications/control