Robotics and automation have greatly enhanced the development of oil and gas by improving maintenance and repair, production efficiency, and safety monitoring. These systems are often equipped with advanced components.

Pumping up Productivity: How Robotics are Used in the Oil and Gas Industry

Pumping up Productivity: How Robotics are Used in the Oil and Gas Industry

Article from | Knight Optical

Here, Knight Optical, a leading provider of high-precision optical components, explores the application of robotics and autonomous technology in the oil and gas industry.

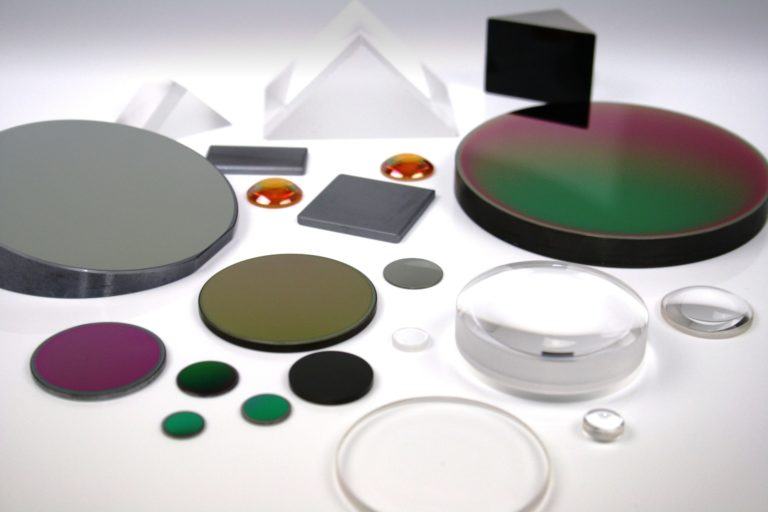

Knight Optical’s high-precision optical components find numerous applications in the oil and gas industry. As well as being used in robotics and automation in this field, optics are utilised in other ways, such as fibre optic sensors, spectroscopy, optical coherence tomography (OCT), and sensing, to name a few. These optical components play an essential role in providing accurate data and insights that aid in optimising site performance and enable operators to make informed decisions.

Oil and gas applications incorporate various optical components to ensure efficient operation, at Knight Optical, there are a wide range of optics we supply for robotic and autonomous oil and gas applications.

How Are Robotics and Automation Used in the Oil and Gas Industry today?

For robotics and automated systems operating on oil and gas sites, optical components can be integrated into systems to facilitate various tasks, such as:

Inspection & Maintenance

Robotic systems are used for inspecting and maintaining elements such as pipelines, wellheads, and other equipment. Here, the use of automated systems reduces the need for human workers to enter potentially hazardous environments and allows for more frequent and thorough inspections.

Exploration

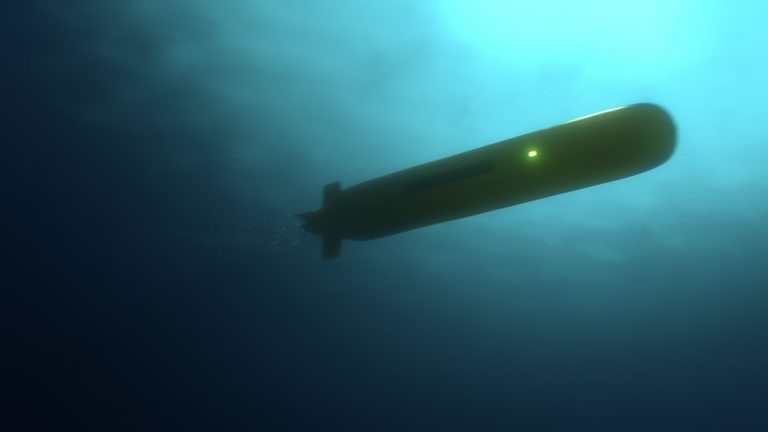

Unmanned aerial vehicles (AUVs) and underwater autonomous vehicles (UAVs), which are automated systems we frequently provide optical components for, are utilised for mapping and surveying oil and gas reserves. These vehicles can access challenging locations and deliver more precise data compared to traditional methods.

Production

Automation is also used for controlling and monitoring the production process in oil and gas facilities. This includes using sensors and control systems to regulate the flow of oil and gas and optimise production efficiency.

Safety

Arguably the most common reason for employment, robotics and automation also, importantly, improve safety in the sector. For example, robots can be used to perform tasks such as gas detection and fire suppression, reducing the risk of injury to human workers.

The Future of the Oil and Gas Robotics

As the oil and gas industry continues to expand, the use of robotics and automation is expected to play an increasingly important role, according to GlobalData1, due to their ability to enhance safety, productivity, and efficiency.

Advances in digitalisation, artificial intelligence (AI), cloud computing, and the Internet of Things (IoT) are contributing to the proliferation of robotic applications in the sector. Consequently, the use of robotics is expected to grow as these technologies continue to evolve and diversify the field’s robotic capabilities.

Anson Fernandes, Oil and Gas Analyst at GlobalData, told Control Engineering in January that the use of robotics in the industry is poised for rapid growth, including various types such as terrestrial crawlers, quadrupeds, aerial drones, autonomous underwater vehicles (AUVs), and remotely operated vehicles (ROVs)1.

What Types of Oil and Gas Robotics or Other Forms of Automation are used?

Robots and automated systems play a crucial role in enhancing working conditions and operations at oil and gas sites, as mentioned earlier.

Here are some common types of systems that are typically found on such sites.

Robots

- Autonomous inspection robots: inspect pipelines, storage tanks and other infrastructure for leaks, cracks, and other defects. They also perform visual and thermal imaging inspections of equipment and structures.

- ROVs: for pipeline inspection, oil rig maintenance, and subsea equipment installation and repair

- Drones: for aerial surveys, mapping, and monitoring of oil and gas pipelines and other infrastructure. They’re also used to monitor in cases of oil spills.

- Teleoperated robots: for maintenance and repairs of oil rigs, pipelines, and other equipment.

Other Automated Systems

- AI: machine learning and natural language processing can be used to improve the efficiency of various processes in the oil and gas sector. For example, to help optimise drilling operations, foresee equipment failures, and analyse data from surveys.

- Process automation: including sensors, control systems, and software to monitor and control various processes in the industry.

Uses of Optics in Automation & Robotic Oil & Gas Applications

Oil and gas applications incorporate various optical components to ensure efficient operation. Overall, it’s imperative that the optics used are designed to withstand harsh environments and provide accurate and reliable data to help improve operational efficiency and safety.

These optics include:

- Infrared sensors: to detect the presence of gas leaks, as well as for temperature monitoring

- Vision systems: to inspect, carry out quality control and for monitoring purposes. These systems typically use cameras and image processing software to analyse images and detect issues.

- LiDAR (Light Detection and Ranging) sensors: to create high-res, 3D images of the environment. They are instrumental in areas where visibility is limited, such as in offshore drilling rigs or underground environments.

More specifically, at Knight Optical, there are a wide range of optics we supply for robotic and autonomous oil and gas applications.

Amongst our most popular options are:

- Infrared (IR) optics: especially Germanium substrates. For these components, we can apply coatings for the 8-12µm region (Long-Wave Infrared [LWIR] thermal waveband) for thermal imaging. These coatings are Antireflective (AR) and Diamond-Like Carbon (DLC) for durability.

- Sapphire Windows: are particularly popular for sensor use as protective windows.

Knight Optical Pumping up Productivity with Premium Optics

The use of robotics and automation in the oil and gas industry has greatly improved safety, efficiency and productivity, and optical components are particularly essential to the performance of these systems. Here at Knight Optical, we’re ready to supply high-precision optical components for the next generation of robotic and autonomous applications for use in the oil and gas industry.

As the oil and gas industry continues to expand, the use of robotics and automation is expected to play an increasingly important role, and Knight Optical is well-positioned to provide the necessary optical components for these evolving technologies.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product