There aren’t a lot of technologies that can propel towering wind turbines to new heights of time and cost efficiencies, but large-format additive manufacturing rose to the challenge and delivered with its eclectic range of applications.

Winds Of Change For Vestas: 3D Printed Tooling Transforms Wind Turbines

Winds Of Change For Vestas: 3D Printed Tooling Transforms Wind Turbines

Case Study from | BigRep

There aren’t a lot of technologies that can propel towering wind turbines to new heights of time and cost efficiencies, but large-format additive manufacturing rose to the challenge and delivered with its eclectic range of applications.

Vestas, a global leader in sustainable energy solutions, designs, manufactures, installs, and services wind turbines across the globe. With more than 160 GW (billion watts) of wind turbines in 88 countries, the renewable energy giant has harvested more wind power than anyone else in the game.

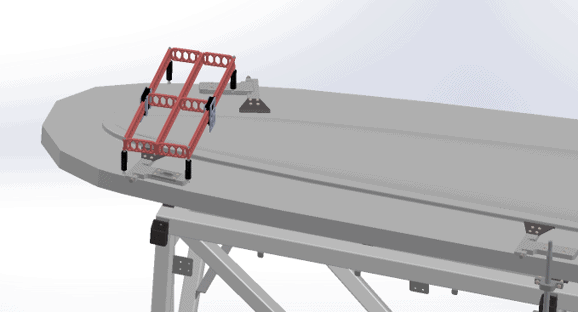

When Vestas needed to replace the jigs and fixtures that help construct their wind turbines, BigRep’s large-format additive manufacturing system was tasked to produce the tooling they needed. The everyday wear and tear of industrial work on traditional metal jigs and fixtures could deform tooling in ways that cause faulty construction. The BigRep STUDIO produced resilient plastic tooling that performed flawlessly and soon Vestas found more applications for the machine than what they had initially invested in.

Ultra Precise Large-Scale Additive Tooling

Vestas' primary requirements were to create jigs and fixtures to position a vital component, the lightning protection system, within the wind turbine's blades. Accuracy is paramount because these blades endure constant inclement weather conditions and are highly susceptible to lightning strikes. The conventional approach is to use steel jigs and fixturing tools but they came with inherent limitations. These metal tools, although robust, faced challenges with deformation and undetectable damages.

The plastic tooling, engineered through additive manufacturing, spelled remarkable advantages over its steel counterpart. Particularly, its lightweight properties, resistance to deformation, and unique ability to yield or break under stress. Fracturing under duress was paramount as these ensured faults were detectable early on which is critical in turbine assembly.

Transitioning from traditional steel tools to advanced polymer-based 3D-printed tooling was one of the highlights of this collaboration with BigRep. The modularity of the newly designed 3D-printed tool simplified Vestas' manufacturing processes, offering versatility to accommodate different configurations with a single adaptable design.

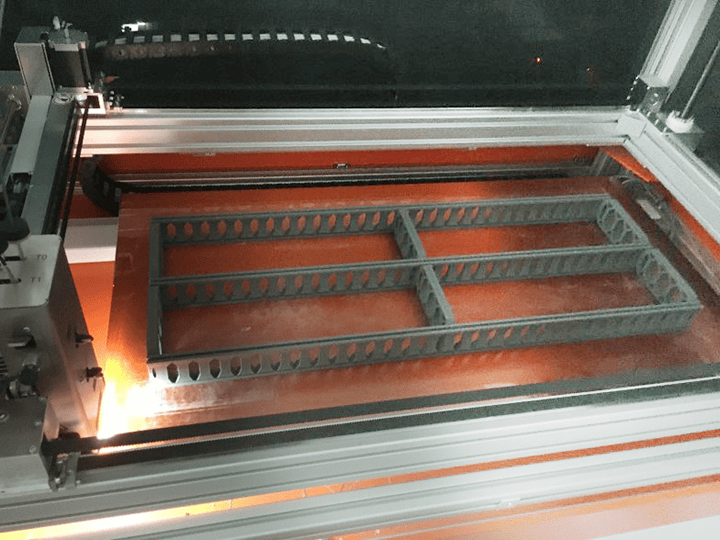

Vestas' tooling for the installation of the lightning protection system being 3D printed on the BigRep STUDIO.

The switch to 3D printed tooling led to significant improvements in both efficiency and cost reduction. Vestas observed a remarkable three-week reduction in lead time and an impressive 72% cost reduction in manufacturing these crucial components. The tooling proved to be highly precise, lightweight, and surpassed traditional manufacturing's accuracy standards by holding measurements down to a couple of microns.

The stability of HIGH-TEMP CF material used for the tools resists changes due to temperature and humidity fluctuations making them reliable. This in turn lowered costs, reduced carbon footprint, and eliminated additional transportation expenses associated with conventional manufacturing methods.

Jeremy Haight, Principal Engineer at Vestas:

"By having Additive Manufacturing in our pocket, we were able to flood the floor with quality tooling, by which we enable our regular production workers to do more of the important spot checks, which results in better quality."

Optimized Manufacturing Efficiency and Field Service Operations

The transition from physical to digital part inventory, enabled by 3D printing, delivered fundamental advantages for Vestas. Additive manufacturing excels in production on demand, small-scale production, and swift iterations in designs, resulting in reduced costs, streamlined logistics, and mitigated expenses linked to conventional manufacturing methods. Additionally, Vestas incorporated smart fixtures, integrating sensors and circuits into their 3D-printed tools to enhance functionality and accuracy.

Given the extensive global reach of Vestas' operations across continents, the challenges associated with lead times for spare parts and expedited costs further underscored the compelling nature of AM solutions. Aligned with Vestas' IoT strategy and Industry 4.0 initiatives, 3D printing bolstered supply chain agility—an essential factor, especially when relying on suppliers in distant countries.

This shift towards digital inventory not only eliminated tax burdens but also significantly enhanced the value of the manufacturing process. The reduced mean time to repair (MTTR) metric served as a marker for increased efficiency and reduced downtime in both manufacturing and field service operations.

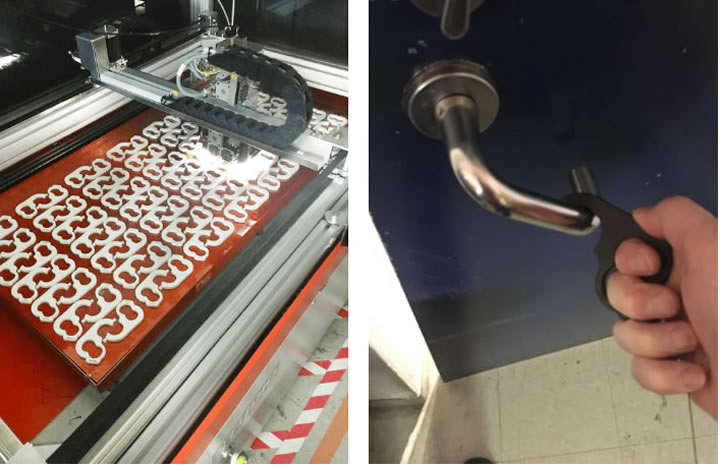

3D Printing in Response to COVID

During the COVID-19 pandemic, Vestas produced over 5,000 personal protective devices with their BigRep STUDIO for frontline workers in healthcare facilities. They designed and produced AM face shields and door claws to help reduce the spread of infection and create safe, hygienic working conditions. The design was made open source which resulted in more than 1000 downloads.

Circularity and Sustainability

Vestas turns their scrap carbon fiber from the manufacturing process into additive manufacturing feedstock. With BigRep's open environment ecosystem, they can upcycle waste into 3D-printed parts and prolong the life of what would otherwise go to waste. The process repurposes and transforms carbon fiber into 3D printing material by grinding, compounding, and filament extrusion:

- Grinding: The waste carbon fiber undergoes a grinding process to break it down into smaller particles. This grinding process reduces the carbon fiber scraps into finer granules, creating a more manageable form for further processing.

- Compounding: The ground carbon fiber particles are then combined with a suitable thermoplastic matrix material. This compounding step involves mixing the carbon fiber granules with the thermoplastic polymer, often through methods like extrusion or compounding machines. This mixture forms a composite material, combining the properties of both the carbon fiber and the thermoplastic.

- Extrusion: The compounded material is then heated and melted before pushing it through a nozzle to create a continuous filament of uniform diameter. This filament, now containing recycled carbon fiber, can be used as feedstock for 3D printing.

Apart from recycling its waste carbon fiber, Vestas also substantially minimized its carbon footprint by maintaining a digital inventory of components and printing them on demand with the BigRep STUDIO. Maintaining physical inventories of components and the logistical burden associated with transporting them across continents are no longer an issue as they are printed at the location required.

Reshaping Wind Energy

By replacing traditional steel tooling with resilient plastic counterparts crafted through additive manufacturing, Vestas advanced its manufacturing capabilities in wind turbine construction. What started as a project to create tools for blade assembly and QA, then extended to the production of spare parts, streamlined supply chains, and later supported COVID initiatives.

With 3D printing, Vestas aligned their production process with their vision: sustainable energy solutions powered by sustainable manufacturing practices.

This article was originally published on the BigRep blog.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product