Turning Your Footsteps into Electricity- A New-Age Innovation

By taking advantage of a sudden energy source, specialists from Switzerland have fostered an energy-gathering gadget that utilizes wood with a blend of silicone covering and installed nanocrystals to create sufficient energy to control LED lights and little hardware.

Producing Energy from Vibrations

Hypothetically, all vibration energy can be transformed into electrical energy; but there are certain types of vibrations that are preferred when the intent is to power a sensor or monitoring system. These vibrations need to have a steady vibration and a controlling frequency.

Rail Energy Storage Harnesses the Power of Gravity All the Livelong Day

Glenn McDonald for Seeker: A California startup is repurposing trains and rail cars to help the storage capacity of renewable energy utilities compete with fossil fuels.

Audi converts potholes to power with new eROT system

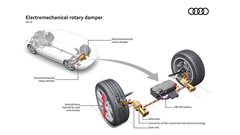

JAKE LINGEMAN for AutoWeek: Aim for those bumps; save the planet. Audi is working on a new suspension system called eROT (electromechanical rotary damper) that turns the kinetic energy of damper travel into usable, fuel-saving power.

“Every pothole, every bump, every curve induces kinetic energy in the car. Today’s dampers absorb this energy, which is lost in the form of heat,” said Dr. Stefan Knirsch, board member for technical development at Audi AG. “With the new electromechanical damper system in the 48-volt electrical system, we put this energy to use. It also presents us and our customers with entirely new possibilities for adjusting the suspension.”

The electromechanical dampers are arranged horizontally and feed electricity from the motion -- 100 to 150 watts on an average road during testing in Germany -- to a lithium-ion battery. A DC converter connects the 48-volt electrical subsystem to the 12-volt primary. Cont'd...

Is Kinetic Energy the Future?

Kinetic energy is power that is gained from motion, and this motion can involve vehicles, individuals, and any other object.

Records 1 to 5 of 5

Featured Product

Vecoplan - Planning and implementation of complete processing plants in refuse derived fuel production

In order to reduce the costs involved in the energy-intensive production of cement, many manufacturers are turning to refuse-derived fuels (RDF), considerably reducing the proportion of expensive primary fuels they would normally use. Solid fuels are being increasingly used - these might be used tyres, waste wood or mixtures of plastics, paper, composite materials and textiles. Vecoplan provides operators of cement plants with proven and robust components for conveying the material and separating iron and impurities, efficient receiving stations, storage systems and, of course, efficient shredders for an output in various qualities.

.jpg)